Waterco helps drought-proof $2M ground water treatment plant

"Providing community access to a secure and reliable water supply"

says John Day,

North East Water executive operations

Setting: Supplying clean and reliable drinking water to the community

North East Water (NEW) operates 21 water treatment plants across north-east Victoria, supplying drinking water to over 100,000 people in an area of approximately 20,000 square kilometres. This region extends from Corryong in the east, along the Murray River to Yarrawonga, then south to Benalla and the alpine towns of Bright, Mt. Beauty and Dartmouth.

NEW’s water treatment processes are determined by a range of factors including:

• The type of catchment

• The chemistry and microbial quality of the water

• Mandatory requirements, such as disinfection and fluoridation

Challenge: Reducing storm-induced turbidity in town water

The town of Wangaratta is located at the junction of the Ovens and King rivers, creating a catchment for the north-western slopes of the Victorian Alps. Heavy rainfall often causes flooding, which in turn increases the number of suspended solids and colloids in the water.

As NEW’s existing plant was unable to extract sufficient dirt from the water, water management specialists and project engineers at Filtec turned to Waterco’s world-renowned filtration solutions.

Solution: Waterco’s AS4020-certified Nozzle plate filtration solutions

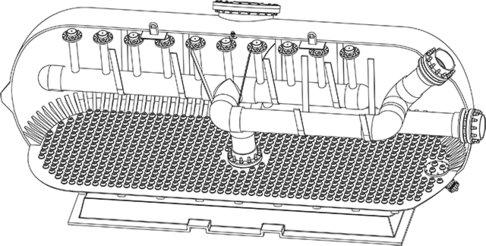

To deliver high-quality filtered drinking water free from unwanted taste and odours, Filtec installed Waterco’s MPD10,000 Commercial Fibreglass Nozzle Plate Media Filter.

To deliver high-quality filtered drinking water free from unwanted taste and odours, Filtec installed Waterco’s MPD10,000 Commercial Fibreglass Nozzle Plate Media Filter (10m² filter area and 1200mm bed depth) – the largest to receive AS/NZS 4020:2005 Certification from the Australian Water Quality Centre. Recognised in many regions around the world, the stringent Australian standard and testing process ensures every component that comes in contact with drinking water does not affect the taste or appearance of water, support the growth of microorganisms, or release cytotoxic or mutagenic compounds or metals.

Waterco manufactures horizontal nozzle plate filters with up to 10m2 filter area and 1,200mm filter media bed depth – the largest to receive AS/NZS 4020:2005 Certification from the Australian Water Quality Centre.

“The process to achieve certification was lengthy, intensive and rigorous, and it included three months of testing in the only lab in Australia that specialises in testing for this standard,” says Waterco’s Andy Gale.

Waterco’s fibreglass Nozzle plate vessels provide NEW with a number of advantages compared with their steel counterparts, including:

• Durability: Fibreglass vessels have a mechanical and chemical resistance superior to steel, plus fibreglass does not rust or corrode and is able to withstand damage from many types of water treatment chemicals. Additionally, they do not leave any unsightly stains

• Effectiveness and efficiency : nozzle plate filters are fitted with a plate and nozzle system, which ensures uniform flow for both filtering and backwashing. This provides maximum performance through the media bed

• Lightweight: Fibreglass tanks weigh only one third that of steel vessels, whilst maintaining the same level of strength. This makes them easy to transport and install

• Easy to maintain: Once installed they are virtually free of maintenance or repairs. This compares with steel vessels, which require the anti-corrosive coating to be maintained periodically, with certified welders required to make repairs to the lining with epoxy coating

Fibreglass vessels have a mechanical and chemical resistance superior to steel, plus fibreglass does not rust or corrode and is able to withstand damage from many types of water treatment chemicals.

Nozzle plate filters are fitted with a plate and nozzle system,

which ensures uniform flow for both filtering and backwashing.

This provides maximum performance through the media bed.

“Certification for a water filtration vessel of this size reinforces Waterco as a manufacturer of superior water filtration solutions that are ideal for a wide range of commercial applications including large public swimming pools, aquatic parks, cooling towers, drinking water systems, desalination plants, industrial processes, zoos, and aquariums,” says Andy.

“That companies such as FILTEC turn to Waterco’s large nozzle plate filters for these solutions is a testament to their durability, effectiveness and efficiency.”

Conclusion: Providing community access to a secure and reliable water supply

North East Water executive operations John Day says, “the new plant will increase Wangaratta’s access to a secure and reliable water supply”.

“Not only can we use it during dirty river events, it allows us to take the main plant off-line at any time to conduct critical infrastructure work,” he explains. “During any future droughts, the new plant will also significantly increase our water resilience and will reduce the frequency of harsh water restrictions.”

Download: wangaratta-case-study-web.pdf